You’ve probably never given them a second thought, blending in the background while we pay little attention. We tend to take much for granted, don’t we?

“Are you talking about elves?”

No, I’m talking about cabinets.

“A cabinet is just that thing you put dishes in. They’re pretty much all the same“

That’s fair, but do you know anything beyond that?

“Um, they’re made by elves?”

That could be true, but let’s look at what we know…

Everything big and small has a history and a science all its own. Cabinets are no different. Instead of attributing this classic furniture design to mystery, let’s explore!

Cabinetry Basics & Designs

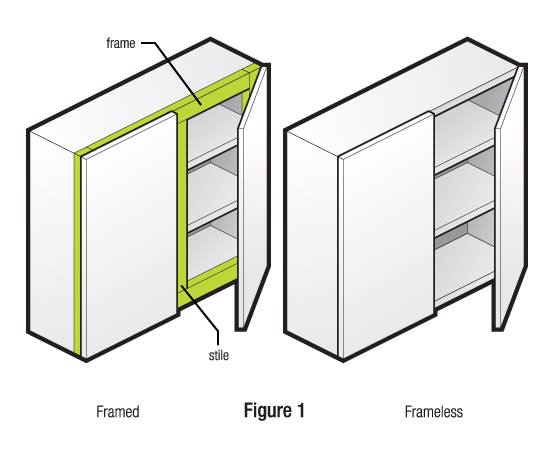

Cabinet construction is limited to two basic designs, framed and frameless. Although similar, they look different, and accessibility varies between the two.

The frame also separates the doors and drawers in various ways. Its edge is aligned with the outside surface of the boxes’ sides and extends out forward only slightly.

It is the more traditional of the two, and its look varies depending on the type of door overlay used. “Door overlay” refers to how much the door or drawer lies over the face frame.

A full overlay covers the face frame completely, while a partial overlay covers only a portion. The doors and drawers may also be made to fit perfectly within the framework—this is called a full-inset. The measurements of overlays will vary per manufacturer.

Frameless Cabinet Construction is easier to access than framed cabinets, as no frame blocks one’s reach. Without a frame, a drawer’s capacity will be greater, as it can extend horizontally from end to end.

Known as a “European” design, the doors are generally full overlay, though they are also available as full inset. In these cases, a veneer protects the box’s raw edges.

Other Style Cabinets

Beyond the above two are other styles based on the cabinet components.

Base cabinets are mounted to the floor and serve as support for countertops. The same concept applies to kitchen islands. Wall cabinets, meanwhile, are mounted against the wall above the countertops, refrigerator, and oven.

Tall cabinets, or pantries, are base cabinets with greater height. They may stand alone or be attached to others.

Construction and Materials

Wood is not the only substance used in kitchen cabinetry. Other materials are incorporated.

Solid wood is through and through, top to bottom, back to front.

Separate panels and boards may be joined together, but as long as the entire assembly is solid wood, it is categorized as solid wood. Be aware that this differs from “all wood,” which we’ll detail shortly.

Engineered from wood particles, chips, and adhesive, Particleboard is a fusion of its ingredients, creating boards and panels. It is the most cost-efficient and extremely common.

MDF (Medium-Density Fiberboard) is also fabricated. Boards and panels are made by fusing wood fibers with an adhesive under pressure. MDF is smoother and denser than particleboard.

Among the array of other cabinet materials is another man-made product, the one most commonly known and used. Plywood (or “all wood”) comprises layers of wood fused by glue in a sandwich configuration.

Often, the directions of the grain are alternated between the panels, strengthening the final product. Plywood is typically sold as an upgrade.

Plastic Laminate is fused with paper and plastic and coats a cabinet’s surface, allowing it to be wiped down and cleaned easily.

Also of plastic, melamine is a covering most popular for use with particleboard, and thermofoil is a vinyl film that is also used to protect the component surface of fabricated wood cabinets.

Not nearly as common as the wood options, all-metal stainless steel cabinets are also produced.

Construction Types

Methods of building cabinets will differ from each other. Not all manufacturers are the same. Plus, there are levels of quality reflected in their respective sticker prices.

When the ends of two boards are notched with ‘V’-shaped cutouts that interlock with each other, it is a form of “joinery”. In this case, the connecting notches are called dovetails.

Another joinery type is Mortise and Tenon. It features a post protruding from the end of a wooden piece that fits tightly into a rectangular hole carved into another section of wood.

A Dado is a groove that’s cut into a board that allows the tight insertion of another board. In the case of a drawer bottom, a dado panel may be slid in and locked into grooves along all four sides, no glue necessary.

Another common joinery technique is the doweled joint, consisting of pegs in holes connected by glue. A butt joint however, combines the flat ends of two pieces that have been ‘butted’ together by glue, screws or nails.

This is partially why glue, screws, nails plus staples are considered unofficial joinery techniques unto their own. They are often employed to reinforce an existing binding but will contribute to less-than-sturdy construction when used individually.

Finishing Styles

The finishing process on wood products is perhaps the most crucial element to a cabinet’s completion. It is pleasing to the eye and essential in protecting the wood from moisture and chemicals. Finishing is an art.

A master can bring out the background highlights while focusing on the detail of the grain pattern, all protected by a level of gloss determined by the process.

It is important to note that finishing does not apply to laminate or melamine surfaces, which provide finish protection inherent to their design.

A painted finish is among the most widely accepted. There are countless colors, though most users prefer an everyday autumn shade.

Wood Stain is a popular treatment that darkens wood, accentuating its natural grain pattern. It is combined with a sealer to create a high-gloss protectant.

Combining oil and resin, varnish becomes a protective coat over the wood and any existing surface treatment. Lacquer is a top-coat sealer, too.

Applied over some of the aforementioned base stains, glaze is a semitransparent coating that enhances the surface, creating subtle visual highlights.

End Process

The finishing process for a cabinet may vary by manufacturer. A large producer may be able to finish multiple cabinets at once, making them more likely to provide consistent results.

Smaller builders may finish each cab individually or outsource them. The process has several inherent steps, such as preparing the wood, applying surface treatments, and baking the finish.

Remember that the options you choose to incorporate into your project will impact your final cost, from when you start until it’s finished. Along the way, you’ll be frustrated to learn there is no shortage of upgrades to consider.

You may decide to save a few bucks and install the cabinets yourself. It could very well be within your means. Otherwise, simply Google ‘cabinet install’ and some local contractors – maybe elves – will appear.

Need help picking a contractor? click here

Need to know about contractors’ warranties? click here